Explosion-proofing

Technical information is provided here explaining the explosion-proof construction required of gas detectors.

Technical information is provided here explaining the explosion-proof construction required of gas detectors.

In (hazardous) locations where gas, vapor, or powder posing explosion risks is present or is assumed to be present in the air—for example, oil refineries and chemical plants—the technical measures (explosion-proof construction) implemented to prevent explosions are collectively referred to as explosion proofing, and devices incorporating such measures are referred to as explosion-proof devices.

An ignition source, combustible material (e.g., combustible gas), and combustion-supporting gas (e.g., oxygen) are referred to as the three factors required for combustion and explosion. No explosion can occur if even one of these factors is missing.

* Ignition source: fire, static electricity, impact, temperature, sparks, or electromagnetic radiation, etc.

* Combustible materials: dust (solid), vapor (liquid), gas, etc.

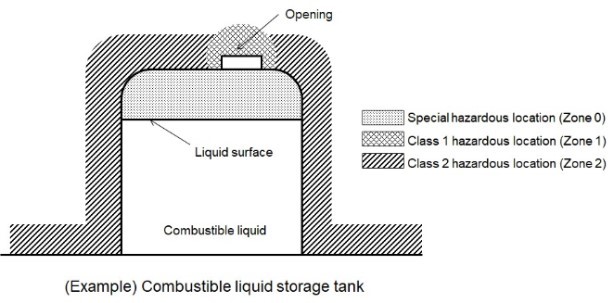

Locations where an explosive atmosphere is present at levels requiring special preventive measures for the construction, installation, and use of electrical equipment or not present:

① Present (or potentially present)

⇒ Hazardous location (explosion-proof area)

② Not present

⇒ Non-hazardous location (non-explosion-proof area)

Riken Keiki gas detectors incorporate one of the following three explosion-proof design approaches.

| Hazardous area | Explosion-proof construction | Remarks |

|---|---|---|

| Special hazardous location (Zone 0) | Intrinsically safe explosion-proof construction (ia) | |

| Resin-filled explosion-proof construction (ma) | ||

| Type 1 hazardous location (Zone 1) | Flame-proof enclosure (d) | Explosion-proof construction items used in special hazardous locations (Zone 0) may also be used. |

| Internal-pressure explosion-proof construction (px, py)) | ||

| Increased safety explosion-proof construction (e) | ||

| Oil-filled explosion-proof construction (o) | ||

| Intrinsically safe explosion-proof construction (ib) | ||

| Resin-filled explosion-proof construction (mb) | ||

| Special explosion-proof construction (s) | ||

| Type 2 hazardous location (Zone 2) | Intrinsically safe explosion-proof construction (ic) | Explosion-proof construction items used in special hazardous locations (Zone 0) or Type 1 hazardous locations (Zone 1) may also be used. |

| Non-incendive explosion-proof construction (nA, nC, nR) | ||

| Resin-filled explosion-proof construction (mc) | ||

| Internal-pressure explosion-proof construction (pz) |

Table 1 Correlation between group and category

| Group | Category (94/4/EC) |

Zone | Presence of explosive atmosphere | |||

|---|---|---|---|---|---|---|

| Group Ⅰ (coal mines) |

M1 | Present (methane, dust) | ||||

| M2 | Potentially present (methane, dust) | |||||

| Group II | 1G | Zone 0 | Present continuously, frequently, or over extended periods | |||

| 2G | Zone 1 | Present intermittently during normal operation (potentially) | ||||

| 3G | Zone 2 | Present occasionally or only for short periods (Not present during normal operation) |

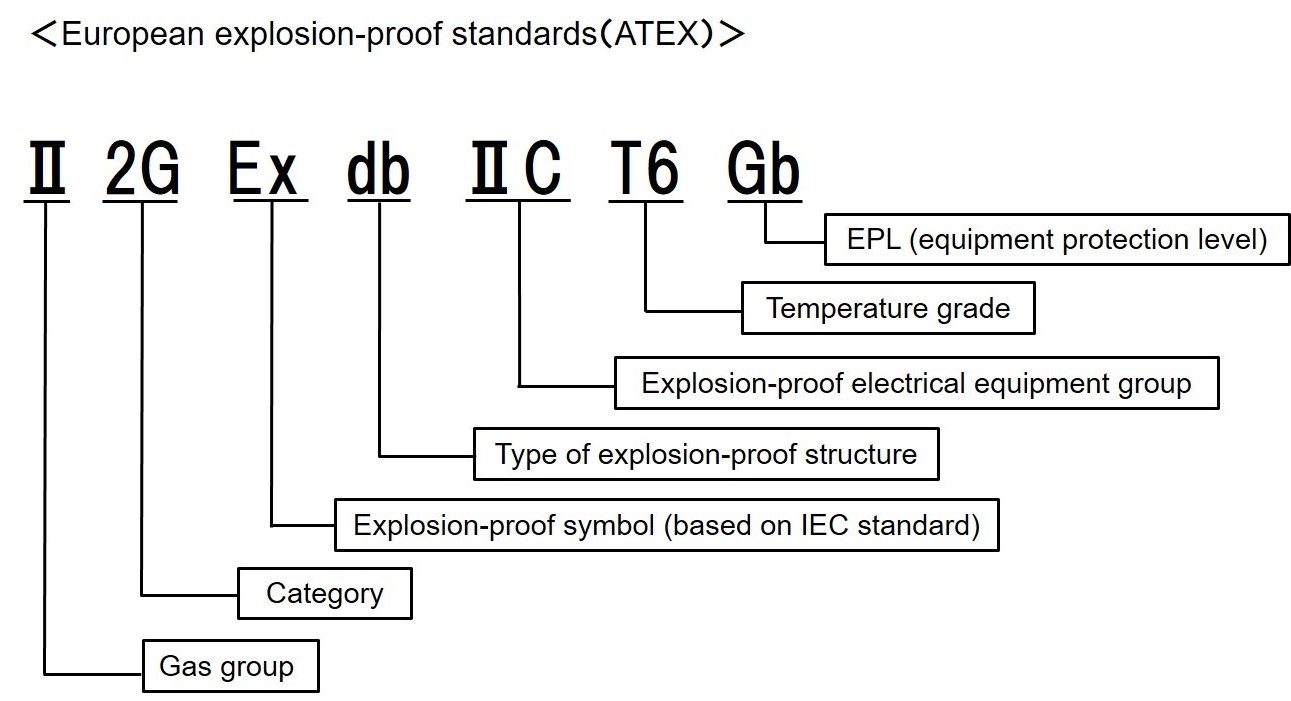

Explosion-proof symbol

Symbol indicating explosion-proof construction.

Explosion-proof construction type

Indicates the type of explosion-proof construction. (See Table 2)

Table 2 Type of explosion-proof construction

| Intrinsically safe explosion-proof construction | i (ia, ib) |

| Flame-proof enclosure | d (da, db) |

| Internal-pressure explosion-proof construction | p |

| Increased safety explosion-proof construction | e |

| Resin-filled explosion-proof construction | m |

| Non-incendive explosion-proof construction | n |

| Oil-filled explosion-proof construction | o |

| Special explosion-proof construction | s |

Explosion-proof electrical device groups

Depending on whether they feature flame-proof enclosures or intrinsically safe explosion-proof construction, respectively, explosion-proof electrical device groups (IIA, IIB, IIC) are classified as maximum safety gap or minimum ignition current. (See Table 3)

Table 3 Explosion-proof devices and explosion-proof class

| Explosion-proof class | Flame-proof enclosure | Intrinsically safe explosion-proof construction |

|---|---|---|

| Maximum safety gap range for gas or vapor | Minimum ignition current ratio range for gas or vapor | |

| II A | 0.9 mm or more | Over 0.8 |

| II B | Over 0.5 mm and less than 0.9 mm | 0.45 or higher and 0.8 or less |

| II C | 0.5 millimeters or less | Less than 0.45 |

* The minimum ignition current ratio is indicated with reference to the minimum ignition current for methane.

Maximum safety gap

This is the maximum joint gap that prevents the propagation of a flame to an external gas mixture through a 25 mm long joint in a flame-proof test container when the gas mixture with the highest flame propagation is ignited inside the specified test container.

Minimum ignition current

This is the minimum current for an inductive or resistive circuit used to ignite the most easily ignitable gas mixture in a spark ignition test.

Temperature grade

This is categorized based on the maximum surface temperature of the electrical device and the ignition temperature of the combustible gas or vapor. Combustible gases and vapor have their own specific ignition temperatures. The methods for measuring ignition temperature are internationally stipulated in IEC 60079-20-1 “Gas and vapour classification - Test methods and data”. Values measured by these measuring methods are often used. (See Table 4)Table 4 Temperature grade and ignition temperature

| Electrical device maximum surface temperature | Temperature class | Combustible gas vapor ignition temperature |

|---|---|---|

| 450 °C or less | T1 | Over 450 °C |

| 300 °C or less | T2 | Over 300 ℃ and 450 ℃ or less |

| 200 °C or less | T3 | Over 200 ℃ and 300 ℃ or less |

| 135 °C or less | T4 | Over 135 ℃ and 200 ℃ or less |

| 100 °C or less | T5 | Over 100 ℃ and 135 ℃ or less |

| 85 °C or less | T6 | Over 85 ℃ and 100 ℃ or less |

Ignition temperature

This refers to the minimum temperature of a heated surface leading to ignition when the heated surface is in contact with a mixture of combustible gas or vapor and air under specified conditions.

EPL (Equipment Protection Level)

Table 5 Explanation of EPL

| EPL | Protection | Zone for normal operation |

|---|---|---|

| Ga | “Extremely high protection” Protected by two independent explosion-proof functions or capable of maintaining explosion-proof performance even when two failures occur independently. ・ Equipment that becomes Ga by itself: Intrinsically safe explosion-proof construction “ia” ・ Two independent explosion-proof structures: Combining equipment with Gb structures |

Zone 0 |

| Gb | “High protection” Maintains explosion-proof performance even under normal operation, and maintains explosion-proof performance even in the presence of frequent severe disturbances to explosion-proof performance or in cases where faults may occur during normal use. ・ Flame-proof and intrinsically safe explosion-proof construction “ib”, flame-proof construction “d”, etc. |

Zone 1 |

| Gc | “Improved protection” Maintains explosion-proof performance only during normal operation. ・ Type n devices |

Zone 2 |

Gas detector groups and temperature grades for typical combustible gases and vapors

| Temperature class Group |

T1 | T2 | T3 | T4 | T5 | T6 |

| II A | Acetone Ammonia Isobutane Ethane Acetate Ethyl acetate Toluene Benzene Methane |

Isopentyl acetate Acetic anhydride Butane Propane Methanol |

Hexane | Acetaldehyde | ||

| II B | Carbon monoxide | Ethanol Ethylene Ethylene oxide |

||||

| II C | Hydrogen gas Hydrogen |

Acetylene | Carbon disulfide |

Reference:

Technical recommendations of the National Institute of Occupational Safety and Health JNIOSH-TR-No.44: 2012 (published by National Institute of Occupational Safety and Health, Japan)